Key Takeaways

Nickel sulphide inclusion (NSI) is a microscopic metallic impurity that can cause toughened glass to spontaneously shatter weeks, months, or years after installation.

Heat soaking process reduces NSI breakage risk from 1 in 10,000m² to 1 in 1 million m² according to Glass and Glazing Federation statistics

NSI breakages create distinctive butterfly-pattern fractures radiating from a central point, requiring electron microscope analysis for confirmation

No glass manufacturers provide warranties against NSI-related failures as it’s considered an inherent risk in toughened glass production

Heat soaking at 290°C for 2 hours remains the most effective method to detect and eliminate problematic glass panels before installation

Imagine walking past a modern office building when suddenly, without warning, a large glass panel shatters and crashes to the ground. No apparent reason, no visible impact, no surface damage – just spontaneous failure. This terrifying scenario represents one of the glazing industry’s most persistent challenges: nickel sulphide inclusion.

This comprehensive guide explores everything you need to know about nickel sulphide inclusion, from its formation during the manufacturing process to prevention strategies that can significantly reduce the risk of spontaneous glass breakage. Whether you’re a glazing professional, architect, or building owner, understanding this hidden threat is crucial for making informed decisions about glass specification and safety.

What is Nickel Sulphide Inclusion

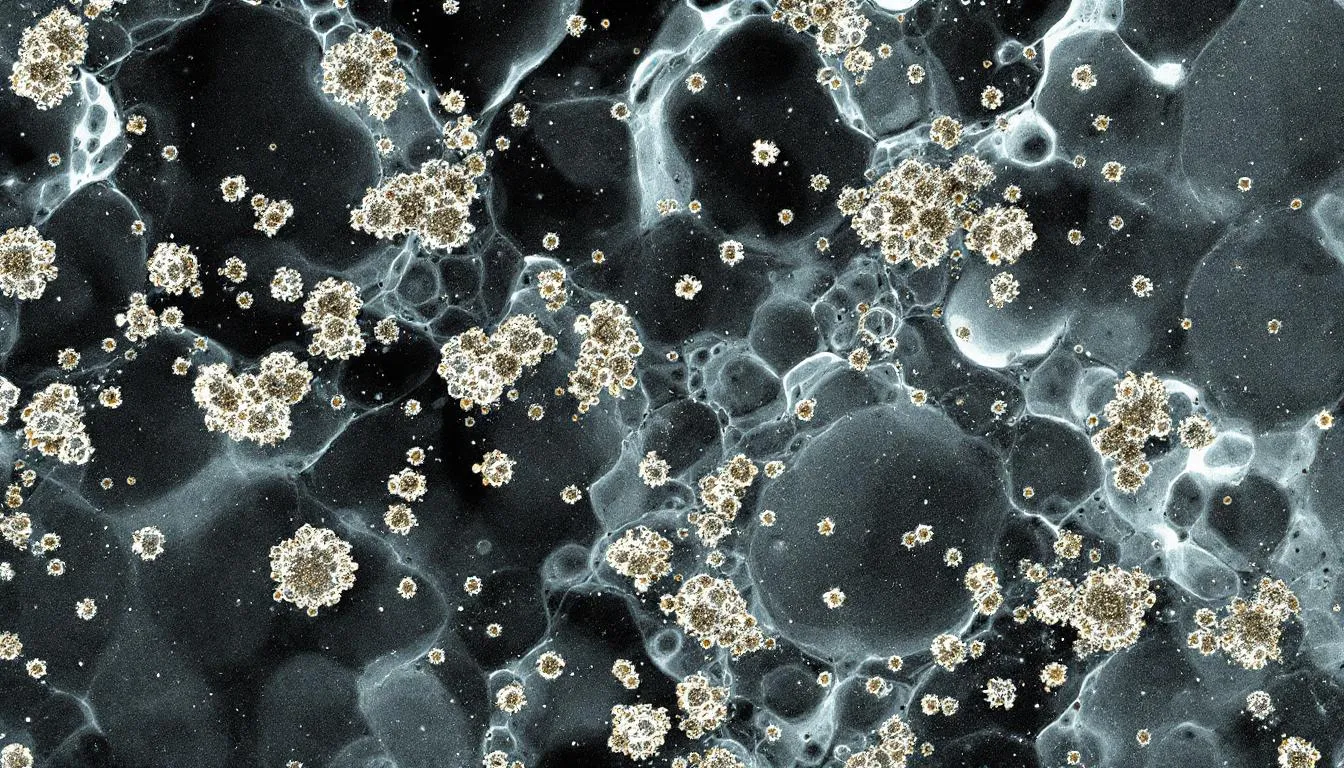

Nickel sulphide inclusion refers to microscopic metallic sulphide particles, typically measuring between 0.05 and 0.5mm, that become embedded within the glass matrix during the manufacturing process. These tiny inclusions remain completely invisible to the naked eye but pose significant structural risks to toughened glass panels.

The formation of nickel sulphide inclusions occurs when nickel contamination from stainless steel equipment combines with sulphur from furnace fuels during glass production. Despite their minuscule size, these inclusions can trigger catastrophic failure in thermally toughened glass due to their unique crystalline properties and expansion characteristics.

Statistics reveal that approximately 1 in every 10,000 square meters of standard toughened glass contains nickel sulphide inclusions capable of causing spontaneous breakage. This occurrence rate varies significantly across different manufacturing facilities and raw materials, with some plants reporting higher incidences due to equipment contamination or fuel source composition.

The Glass and Glazing Federation has documented that float glass production, which accounts for the majority of architectural glazing, presents the highest risk for nis inclusion formation. The rapid cooling process essential for creating toughened glass traps the nickel sulphide particles in their high-temperature crystal structure, setting the stage for future expansion and potential failure.

While other inclusions exist in glass – over 50 types have been identified – nickel sulphide stands apart due to its specific thermal transformation properties. Unlike other contaminants that remain stable, nis particles undergo a time-dependent phase change that generates internal stress sufficient to overcome the tensile strength of even high-quality toughened glass.

Formation Process During Glass Manufacturing

The formation of nickel sulphide inclusions begins during the glass making process when raw materials including silica sand, soda ash, and limestone are heated to temperatures exceeding 600°C in industrial furnaces. During this melting phase, nickel contamination typically enters the system through stainless steel components in the manufacturing equipment or as trace elements in fuel sources.

Sulphur is deliberately introduced into the molten glass as sodium sulphate, serving as a fining agent to eliminate air bubbles and improve optical clarity. When nickel contaminants encounter this sulphur-rich environment at high temperatures, they react to form nickel sulphide compounds that become dispersed throughout the molten glass.

The critical moment occurs during the tempering process, when the glass is rapidly cooled from approximately 700°C to room temperature in a matter of seconds. This rapid cooling, essential for creating the compressive surface stresses that give toughened glass its strength, also traps the nickel sulphide particles in their high-temperature beta-phase crystal structure.

Over time, spanning weeks to years, these trapped nis inclusions slowly convert from their high-temperature state to the original low temperature structure known as the alpha-phase. This transformation results in a volume expansion of approximately 2-4%, creating localized stress within the rigid glass matrix.

The time required for this phase change varies dramatically depending on ambient temperature conditions, with higher temperatures accelerating the transformation process. At room temperature, the conversion can take months or even years, making the timing of spontaneous failure essentially unpredictable.

When the expanding nickel sulphide particle generates enough tension to exceed the glass’s tensile strength at its singular point of weakness, catastrophic failure occurs. The internal stress pattern of toughened glass means that once initiated, the crack propagates rapidly throughout the entire panel, causing complete shattering.

Identifying NSI Breakage Patterns

Nickel sulphide inclusion breakages produce distinctive fracture patterns that trained professionals can recognize, though definitive confirmation requires sophisticated analysis. The characteristic “butterfly” or figure-of-eight pattern radiates outward from a central point where the nis particle was located, creating a unique signature different from impact or thermal stress failures.

Surrounding the break origin, glass fragments typically form pentagonal and octagonal shapes, contrasting with the more random fragmentation patterns seen in other types of glass failure. These geometric fragment shapes result from the specific stress wave propagation through the toughened glass structure when failure initiates from an internal point source.

However, identifying the exact cause of spontaneous breakage can be challenging when glass shatters into thousands of pieces, particularly if the panel falls from height or experiences secondary impacts. Professional investigation often requires collecting fragments and conducting electron microscope analysis to locate and confirm the presence of nickel sulphide particles at the failure origin.

The Glass and Glazing Federation has documented specific visual characteristics that help distinguish nis-related failures from other causes. Unlike impact breakage, which shows clear contact points and radiating cracks, or thermal stress fractures that typically originate from glass edges, nickel sulphide inclusion breakage always initiates from an interior point within the glass panel.

Time of occurrence also provides important clues, as spontaneous glass breakage due to nis inclusion rarely happens immediately after installation. Most documented cases occur weeks, months, or years after the glass has been in service, often triggered by temperature fluctuations that accelerate the crystalline phase transformation.

Professional glaziers and forensic glass experts use specific protocols when investigating suspected nis breakages, including photographic documentation of fracture patterns, careful collection of key fragments, and laboratory analysis using scanning electron microscopy to definitively identify the presence of nickel sulphide particles.

Heat Soaking Process and Standards

The heat soaking process represents the most effective known technology for detecting and eliminating glass panels susceptible to nickel sulphide inclusion breakage. This thermal treatment, governed by EN 14179 standards, involves controlled heating of toughened glass panels to accelerate the crystalline transformation that causes spontaneous failure.

Process parameters are precisely specified: glass panels must be heated to 290°C (plus or minus 10°C) and maintained at this temperature for a minimum of two hours. This controlled environment accelerates the conversion of nickel sulphide particles from their high-temperature beta-phase to the low-temperature alpha-phase, triggering breakage in problematic panels before they leave the factory.

The heat soaking process works by compressing months or years of natural phase transformation into a two-hour testing period. Any glass panel containing nis inclusions large enough to cause future spontaneous failure will typically break during this test, allowing manufacturers to identify and discard defective units before they reach the installation site.

Industry statistics demonstrate the remarkable effectiveness of heat soak testing. According to Glass and Glazing Federation research, properly conducted heat soaking eliminates approximately 95% of glass panels susceptible to nickel sulphide inclusion breakage, reducing the overall failure rate from 1 in 10,000 square meters to approximately 1 in 1 million square meters.

However, heat soaking significantly impacts lead times and project costs. The process typically adds 2-3 weeks to standard glass production schedules, and the additional energy costs, handling requirements, and potential panel losses during testing can increase glass prices by 15-25% compared to standard toughened glass.

The remaining 5% risk factor exists because some extremely small nis inclusions may not generate sufficient stress to cause failure even under accelerated test conditions, yet could still pose long-term risks under specific environmental conditions or after years of gradual expansion.

Effectiveness and Limitations of Heat Soaking

Heat soaking provides substantial risk reduction but cannot guarantee complete elimination of nickel sulphide inclusion breakages. The process effectively identifies and removes the vast majority of problematic glass panels, but inherent limitations mean that absolute certainty remains technically impossible with current technology.

The 95% elimination rate achieved through heat soak testing represents a significant improvement over untreated toughened glass, reducing spontaneous breakage incidents from approximately 1 in 10,000m² to 1 in 1 million m² of installed glass. This dramatic risk reduction makes heat soaking the industry standard for critical applications where glass failure could pose safety risks or result in significant property damage.

Secondary damage during the heat soaking process presents an additional consideration. When a panel breaks during testing due to nis inclusion, the fracture can occasionally damage adjacent panels in the same furnace load. While this occurs in less than 1% of heat soak cycles, it represents an additional cost factor that must be considered in project planning.

The economics of heat soaking involve balancing the additional upfront costs against the potential consequences of spontaneous breakage. For overhead glazing, structural glazing, or applications where glass failure could endanger occupants, the relatively modest cost increase typically justifies the substantial risk reduction achieved.

Processing techniques continue to evolve, with some manufacturers developing enhanced heat soak protocols that extend testing duration or modify temperature profiles to improve detection rates. However, these modifications must be carefully balanced against increased energy costs and potential impacts on glass optical or mechanical properties.

Glass Types and NSI Susceptibility

Different glass types exhibit dramatically varying susceptibility to nickel sulphide inclusion breakage, with thermally toughened glass showing the highest risk due to its internal stress characteristics. The rapid cooling process that creates toughened glass’s compressive surface layer also generates high tensile stresses in the interior, making the glass particularly vulnerable to failure when nis particles expand.

Standard annealed glass, which cools slowly during production, allows nickel sulphide inclusions to safely transform to their low-temperature state during manufacturing. This gradual cooling process means that any volume expansion occurs while the glass is still soft enough to accommodate the stress, effectively eliminating the risk of spontaneous breakage from nis inclusion.

Heat-strengthened glass represents a middle ground between annealed and fully toughened glass. While stronger than annealed glass, heat strengthened glass undergoes less aggressive cooling, resulting in lower internal stresses that significantly reduce the risk of nis-related failure compared to fully toughened panels.

Glass Type | NSI Breakage Risk | Cooling Process | Internal Stress Level |

|---|---|---|---|

Annealed Glass | Negligible | Slow cooling | Low tensile stress |

Heat Strengthened Glass | Low | Moderate cooling | Medium tensile stress |

Thermally Toughened Glass | High | Rapid cooling | High tensile stress |

Laminated glass configurations offer enhanced safety even when one layer experiences nis breakage. While the broken layer may shatter due to nickel sulphide inclusion expansion, the intact layer continues to provide structural support and prevents glass fragments from falling. This makes laminated constructions particularly valuable for overhead or structural glazing applications.

Float glass production methods influence nis inclusion formation rates, with some manufacturing facilities reporting higher incidences based on their specific equipment configurations and raw material sources. Understanding these variations helps glazing professionals make informed decisions about sourcing glass from suppliers with robust quality control systems.

The choice between glass types involves balancing strength requirements, safety considerations, and nis breakage risks. For applications where the consequences of spontaneous breakage are minimal, standard toughened glass may be appropriate. However, critical applications increasingly specify heat soaked glass or alternative constructions to minimize risk.

Warranty and Insurance Considerations

The glazing industry maintains a consistent position regarding nickel sulphide inclusion: no major glass manufacturer provides warranties against nis-related failures. This universal exclusion reflects the inherent nature of the problem and the current technological limitations in completely preventing or detecting all potentially problematic inclusions.

Guardian Glass UK, along with other leading manufacturers, explicitly states in their standard terms that spontaneous breakage due to nickel sulphide inclusion falls outside warranty coverage. This position acknowledges that nis formation is an inherent characteristic of the toughened glass manufacturing process rather than a manufacturing defect in the traditional sense.

Building owners and facility managers must therefore look to insurance coverage for protection against nis-related breakage incidents. Most comprehensive commercial property insurance policies include coverage for spontaneous glass breakage, though specific terms and deductibles vary significantly between providers and policy types.

Home insurance policies typically provide coverage for accidental glass breakage, which may include spontaneous failures due to nickel sulphide inclusion. However, policy holders should verify coverage details with their insurance providers, as some policies may exclude or limit coverage for certain types of glass failures.

The absence of manufacturer warranties places additional emphasis on proper specification and risk assessment during the design phase. Specifying heat soaked glass for critical applications becomes even more important when warranty protection is unavailable and insurance claims may involve significant deductibles or coverage limitations.

Legal liability considerations also come into play when nis breakage occurs in public spaces or causes property damage. While manufacturers disclaim warranty coverage, questions of negligence or inadequate specification could potentially arise if appropriate risk mitigation measures were not implemented during design and construction.

Professional indemnity insurance for architects and glazing contractors may provide some protection against claims related to glass specification decisions, but coverage terms vary widely and typically require demonstrating adherence to recognized industry standards and best practices.

Prevention Strategies and Alternative Solutions

Heat soaking remains the most proven and widely implemented strategy for reducing nickel sulphide inclusion risks, but emerging technologies and alternative approaches offer additional options for risk mitigation. Understanding when to specify heat soaked glass and how to evaluate alternative solutions enables more informed decision-making for critical applications.

Specifying heat soaked glass becomes essential for applications where spontaneous breakage could pose safety risks or result in significant property damage. Overhead glazing, structural glazing, large curtain wall panels, and installations in high-traffic areas typically justify the additional cost and lead time associated with heat soak testing.

Emerging detection technologies, including ultrasound imaging and advanced laser inspection systems, show promise for identifying nis inclusions without requiring destructive testing. However, these technologies remain largely experimental and have not yet achieved the reliability or cost-effectiveness needed for widespread commercial adoption.

Fuel source modifications in glass manufacturing have provided modest improvements in reducing nickel contamination. Plants that have switched from oil-based fuels (which contain trace nickel) to natural gas have reported lower but not eliminated nis inclusion rates. This approach addresses one contamination source but cannot eliminate nickel from equipment or raw materials.

Raw material improvements and enhanced quality control systems have evolved significantly since the early 2000s. Modern glass manufacturers implement more rigorous screening of sand and other inputs, improved stainless steel equipment maintenance protocols, and better monitoring of furnace conditions to minimize nis formation opportunities.

Alternative glass constructions offer practical solutions for specific applications. Using annealed glass in laminated constructions can provide strength and safety while eliminating nis breakage risk. However, this approach may not meet all structural or thermal performance requirements.

Real-World Case Studies

The London City Hall project experienced several documented nickel sulphide inclusion breakages approximately two years after completion, despite representing modern architectural design and construction practices. These incidents occurred in the building’s distinctive curved glass facade, requiring expensive panel replacements and raising questions about long-term maintenance costs for large-scale glazing projects.

The breakages at City Hall demonstrated the unpredictable timing characteristic of nis failures. Despite the glass being installed according to current industry standards and the building achieving BREEAM Excellent certification, spontaneous failures occurred well after the initial construction warranty period, highlighting the long-term nature of the risk.

Investigation of the City Hall incidents revealed the characteristic butterfly fracture patterns and confirmed nickel sulphide inclusion as the failure mechanism through electron microscope analysis. The scattered timing of the breakages – occurring over several months rather than all at once – illustrated the random nature of the crystalline transformation process.

In contrast, the Rock Cove cantilevered house project in Scotland implemented comprehensive heat soak testing for all toughened glass elements due to the structural glazing design and remote location. This decision, while increasing project costs by approximately 20%, provided confidence that spontaneous breakage incidents would be minimized throughout the building’s service life.

The cost-benefit analysis from Rock Cove demonstrated that heat soaking expenses were justified by the combination of structural glazing requirements, difficult access for maintenance, and the high cost of emergency glass replacement in the remote location. The project has operated for over five years without spontaneous breakage incidents.

Commercial building case studies show varying approaches to nis risk management. High-rise office buildings increasingly specify heat soaked glass for critical elements while accepting standard toughened glass for less critical applications, balancing cost considerations against risk exposure.

Insurance claim data from major UK insurers indicates that nis-related breakage incidents result in average claims of £2,000-£15,000 per occurrence, including emergency glazing, temporary weather protection, and disruption costs. These figures help justify the cost of heat soaking for many commercial applications.

FAQ

Can NSI be detected before glass installation without heat soaking?

Currently, no commercially viable non-destructive testing method exists for detecting nickel sulphide inclusions in finished glass panels. The particles are microscopic (0.05-0.5mm) and invisible to the naked eye, requiring sophisticated electron microscope analysis for identification. While experimental ultrasound and laser imaging technologies show promise, they remain in research phases and are not yet available for practical application in glass manufacturing or installation.

What happens if NSI breakage occurs in structural glazing applications?

Nickel sulphide inclusion breakage in structural glazing creates serious safety concerns since the glass panels provide structural support for the building envelope. When nis breakage occurs, the affected panel loses all structural capacity immediately, potentially overloading adjacent panels and creating cascade failure risks. Emergency temporary support must be installed immediately, and replacement typically requires specialized engineering assessment and high-access equipment, resulting in significant costs and potential building closure.

Are there any legal requirements for disclosing NSI risks to building owners?

While no specific legislation mandates nis risk disclosure, professional liability considerations and duty of care requirements mean that architects and glazing contractors should inform clients about spontaneous breakage risks when specifying toughened glass. Industry best practice involves discussing heat soaking options during design phases, particularly for overhead or structural glazing applications. Building regulations may indirectly address nis risks through safety glazing requirements in specific locations.

How do environmental factors like temperature fluctuations affect NSI transformation rates?

Temperature fluctuations significantly accelerate the crystalline phase transformation that leads to spontaneous breakage. Higher ambient temperatures, solar heating, and thermal cycling all speed up the conversion of nickel sulphide particles from their high-temperature beta-phase to the low-temperature alpha-phase that causes expansion. This explains why nis breakages often occur during summer months or following significant temperature changes, and why heat soaking at 290°C effectively accelerates the transformation process for testing purposes.

What are the latest research developments in NSI prevention and detection methods?

Current research focuses on several promising areas including advanced non-destructive testing using acoustic emission monitoring, improved raw material screening techniques, and alternative glass tempering processes that might reduce internal stress levels. Some manufacturers are investigating modified glass compositions that could minimize nis formation, while others explore enhanced heat soaking protocols with extended duration or modified temperature profiles. However, none of these technologies have yet achieved commercial viability or regulatory approval for widespread implementation.